- Model NO.: bu

- Forging Forming Method: Free Forging

- Feature: Automation

- Warranty: 12 Months

- Advantage: Easy to Maintenance

- Thickness: 0.8-1.6mm

- Transport Package: Wood

- Origin: Shandong Jinan

- Type: Rolling Machine

- Power Source: Electric

- Certification: CCC, ISO9001, CE

- Customized: Customized

- Condition: New

- Trademark: brotherunion

- Specification: 30M

- HS Code: 8455221000

The line is composed by loading car, uncolier, guiding & feeding device, roll forming machine, cutter, automatic stacker, hydraulic system, electric control system.

C purlin Specification Table

Z purlin Specification Table

INBON MACHINERY Was Founded By Metalforming experts In All Aspects of Tooling Design, Hyrdaulic & Electrical Design, software programming in 2008. We now consider ourselves as the leading pioneer of roll forming industry in China because of years of experience on providing high-end machinery for both local and oversea markets.

We offer the best balance between affordability and quality, thanks to the lower cost of China today that we build quality machines for a price that can take your business to another level. We use components that are all well-known brands and are used on equipment throughout the world.  We are now supplying machines in excellent level of quality, accuracy, speed and most importantly a complete range for many industries such as for PEB building, construction, automobile framing, Shelving and Racking, infrastructure, solar energy etc.. Our machine are featured with most up-to-date technology to comply with modern metalforming production, and made to clients' specific needs, and we are also glad to provide you years of insigh, knowledge, and expertise in our fields.Â

Please no hesitate to contact with us, and together we form our brighter future with steel!

| Â | Â | 1 | Â | |

| 5 | Servo Feeding Device | Drive by Servo Motor |  |  |

| 6 | Punching and pre-cutting Device | Punching Hole and pre-cut the sheet to fixed length | 1 |  |

| 7 | Guide Feeding Device | Vertical Roll Guide | 1 |  |

| 8 | Roll Former | Individual Roller Station | 1 |  |

| 9 | Automatic stacker |  | 1 |  |

| 10 | Hydraulic System | Dedicated System | 2 |  |

| 11 | Electric Control Section | Control Production Line | 1 |  |

| 12 | Remote network system |  | 1 |  |

| 13 | Spare Parts |  | 1 |  |

| 14 | Manual of the machine |  | 1 |  |

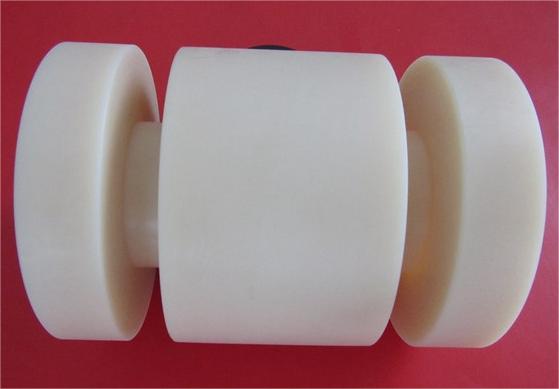

HONY®Nylon 6 is also a commonly used material in precision machining. It is often used to process small precision fixtures. Due to the hardness, toughness and processing characteristics of nylon materials, it plays an irreplaceable role in the processing of precision parts.

HONY®MC Nylon (Nylon) polyamide, English name Polyamide (abbreviated as PA), density 1.16g/cm3, is the main chain of molecules containing repeated amide groups - [NHCO]- thermoplastic resins in general, including aliphatic PA, aliphatic - aromatic PA and aromatic PA. aliphatic PA variety, production, widely used, its name by the synthesis of monomer specific The name is determined by the specific number of carbon atoms in the synthesis monomer.

Nylon products are widely used, is a good material for plastic instead of steel, iron, copper and other metals, is important is MC cast nylon instead of wear-resistant parts of machinery and equipment, instead of copper and alloy for wear-resistant parts of equipment. Suitable for making wear-resistant parts, transmission structure parts, conveying sliding parts, automobile manufacturing parts, chemical machinery parts, chemical equipment and other parts. Such as gears, rollers and casters, bushings, skids and pulleys, impellers, conveyor rollers, structural connectors, sealing rings and gaskets, screws and nuts, etc.

1. High strength, able to bear the load for a long time.

2. Good resilience, able to bend without deformation, while maintaining toughness, resisting repeated impact.

3. Wear-resistant self-lubricating, providing better than bronze cast iron carbon steel and phenolic laminate in oil-free (or de-oiled) lubrication applications, reducing consumption and saving energy.

4. Noise absorption, vibration damping, MC nylon modulus is much smaller than metal, the attenuation of vibration is large, providing a practical way to prevent noise better than metal.

5. Compared with metal, MC nylon hardness is low and does not damage to the wear parts.

6. Continuously withstand the working temperature of -40~100℃

HONY®MC Nylon including :

Nylon 6

Outstanding toughness, temperature resistance -40-110 degrees, excellent wear resistance, slightly worse dimensional stability, moderate price, mostly used for one-time injection molding.

Nylon 66

Toughness and strength are outstanding, temperature resistance -50-130 degrees, excellent wear resistance, general dimensional stability, higher price, mostly used for one-time injection molding

MC nylon

Toughness and strength are outstanding, temperature resistance -40-110 degrees, excellent wear resistance, general dimensional stability, moderate price, the product is mostly made of rods, tubes, plates profiles, single product can be a few grams to hundreds of kilograms.

Change the name of nylon

1. Glass fiber reinforced nylon: increased strength, reduced toughness, increased temperature resistance.

2. Carbon fiber reinforced nylon: strength increased to the limit of nylon, slightly lower toughness, temperature resistance increased to the limit of nylon.

3. Molybdenum disulfide self-lubricating wear-resistant nylon: reduce the coefficient of friction and improve the wear resistance of the product.

4. Oil-containing self-lubricating wear-resistant nylon: reduce the coefficient of friction and improve the wear resistance of the product.

5. Low temperature resistant toughened nylon: increase the toughening agent proportionally to improve the toughness of the product, so that it will not be brittle in low temperature environment.

6. High temperature resistant nylon: the highest use temperature can reach 260 degrees.

Features of PA6 processing part PA gears:

Nylon has good comprehensive properties, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication, and has a low coefficient of friction, has certain flame retardancy, and is easy to process. It is suitable for glass fiber and Other fillers are filled and modified to improve performance and expand application range.

Due to its non-toxic, light weight, excellent mechanical strength, wear resistance and good corrosion resistance, nylon is widely used to replace copper and other metals in the manufacture of bearings, gears and pumps in machinery, chemical industry, instrumentation, automobile and other industries. leaves and other parts. Polyamide has high strength after melt spinning and is mainly used as synthetic fiber and as medical suture.

Corrosion resistance: Nylon has very good chemical stability and is very stable to almost any chemical reagent, even at higher temperatures, it can still maintain good chemical stability. In addition, it is also resistant to hot water and steam. It can be used for a long time in the steam of 200~250 ℃.

Heat resistance: Nylon has a higher melting point, generally above 240°C. The heat resistance of aromatic nylon is higher than that of aliphatic nylon. If certain reinforcing fillers are added, its thermal stability will be greatly improved, and the heat distortion temperature can be as high as 250 ℃.

PA6 Screw Machine Parts Solvent resistance: Nylon has good chemical stability, alkali resistance, and weak acid resistance; it is also a solvent-resistant plastic, especially resistant to aromatic compounds and common organic solvents, and can be used in chemical and chemical instruments; in environments where certain metals are prone to rust , such as water meters, can be replaced by nylon materials.

Benefits Of Machining Nylon Polyamide:

High amount of insulation and resistance to corrosion, impact, and abrasion.

Nylon is lighter, stronger and offers high wear resistance, providing longer-wearing machined parts that require less maintenance than metal.

Nylon is ideal for the production of fire-resistant items since it melts NOT burn.

High tensile strength and elasticity modulus.

Types Of Milling PA6 6 Nylon:

Fittings

Bushings

Rivets

Washers

Threaded components

PA gears,PA PA6 processing part,Machining Nylon Polyamide,Milling PA6 6 Nylon,PA6 Screw Machine Parts,PA6 processing part,CNC PA6 component

Hony Engineering Plastics Limited , https://www.honyplastic.com