- Company: JKU/Institut für Polymer Product Engineering

- Country: Austria

- Industry: Academy

- Solutions: Moldex3D Advanced Package; Flow, Pack, Cool, Warp, Fiber, Designer BLM

The JKU has been around for 50 years. Today, over 20,000 students are currently enrolled in an academic degree program at the JKU. As Upper Austria’s largest institution of research and education, the university has a lot to offer: an outstanding selection of academic degree programs on one hand and on the other, it is a place to be happy. (Source: https://www.jku.at/en/)

Edited by Alvin Hsu, Account Manager of Moldex3D Europe

Summary

Warpage prediction is essential to ensuring product quality and complying with specifications of unfilled and short fiber reinforced injection molded polymer components. Therefore, it is necessary to consider the viscoelastic behavior of thermoplastic polymers in order to get accurate simulation results. In this project, Moldex3D was used to investigate the effect of viscoelasticity on the warpage analysis. A methodology for the modeling and simulation of the warpage behavior plus its validation was developed. The validation was performed in a test component and experimental 3D scans. The result showed that having correct characterization and description of the viscoelastic behavior is vital to achieving accurate warpage behavior.

Challenges

- To develop a methodology for simulating and validating part warpage

- To understand the importance of viscoelasticity in warpage analysis

- To reduce warpage and maintain dimensional stability in actual production

Solutions

Moldex3D was used to carry out the full transient analyses (Ct-F-P-Ct-W) employing the Standard warpage as well as the Enhanced Warpage Solver to predict the warpage behavior. Finally, 3D-Scans utilizing an ATOS Triple Scan III device from GOM GmbH was used to validate the simulation results.

Benefits

- The warpage results of the point with maximum absolute displacement could be improved by about 520 % for the homopolymer and by about 78 % for the short fiber reinforced polymer employing viscoelastic behavior compared to using the standard warpage solver with elastic models

- Identified the key factors affecting warpage

- Avoided the costly trial-and-error process in mold design via virtual prototyping

Case Study

The research, done by the doctoral student Philipp Siegfried Stelzer, was conducted during an internship program at the Moldex3D headquarters in cooperation with Professor Major of the Institute of Polymer Product Engineering (JKU Linz, Austria) and the company Polyplastics Europe GmbH (Frankfurt am Main, Germany).

A correct warpage prediction is essential to ensuring product quality. In order to accurately predict the warpage tendency and value, the material properties play important roles in the simulation. This project is aimed to validate the importance of viscoelasticity for an accurate warpage prediction.

Two materials were used in the benchmark test, one pure PBT thermoplastic polymer and one PBT with 30 w% short glass fiber. The project included a comprehensive characterization of the raw materials to obtain thermo-rheological and mechanical properties necessary for Moldex3D simulation. Dynamic mechanical thermal analyses (DMA) were carried out to generate master curves for the calibration of the viscoelastic models by fitting the Prony series. The benchmark component was a plastic injection molded rib box, and the 3D scans were performed by utilizing an ATOS Triple Scan III device to validate the simulation results.

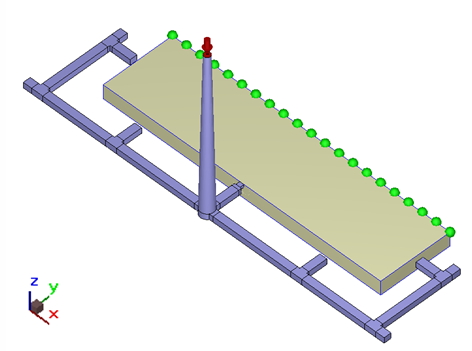

Moldex3D BLM mesh was used in the preparation of the model. All cold runner and cooling channels were built based on real tool design. 21 measure nodes were placed for quantitative validation of Z-displacement (Fig. 1).

Fig. 1 Simulation model of the benchmark component.

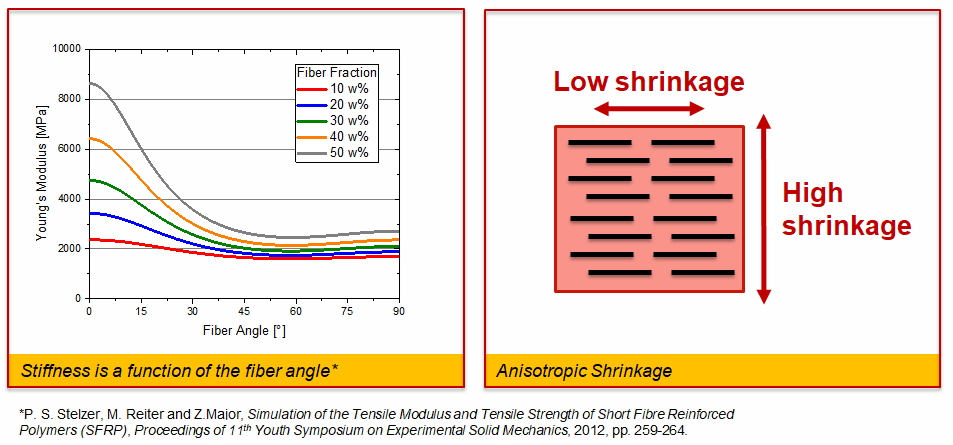

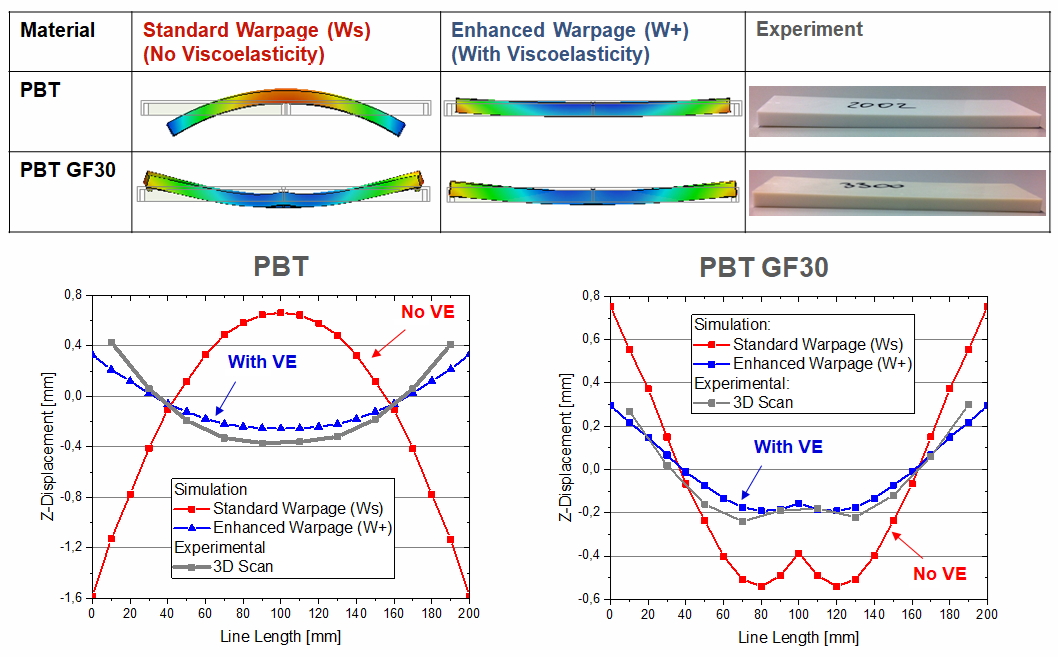

Full Moldex3D transient analyses (Ct-F-P-Ct-W) with Standard Warpage, as well as Enhanced Warpage solvers, were performed to predict the deformation. For neat PBT polymer, using a Standard solver without considering viscoelasticity failed to correctly predict the warpage trend. While using the Enhanced solver, which considers the viscoelastic behaviors, the warpage trend was successfully captured with a fairly close value. For the fiber-reinforced PBT, on the other hand, both Standard and Enhanced solvers were able to predict the correct warpage trend because flow-induced fiber orientation will dominate the warpage behavior due to its anisotropic property (Fig. 2). However, considering viscoelasticity could significantly improve the absolute value of Z-displacement. (Fig. 3)

Fig. 2 Anisotropic property of fiber-reinforced material

Fig. 3 Validation results of the warpage prediction for both PBT materials.

Results

In conclusion, the viscoelastic property of the material was proven to be vital to a precise simulation. With the consideration of viscoelasticity, Moldex3D can improve the accuracy of warpage predictions after considering the viscoelasticity, whether it is predicting pure or fiber-reinforced plastic.

Nantong Zhongyi Electronic Technology Co., Ltd. , https://www.apl-pickleball.com